Understanding Electrical Hazards in the Workplace

Electrical hazards can cause serious injuries and even fatalities if not addressed properly. According to the Occupational Safety and Health Administration (OSHA), electrical incidents rank among the top causes of workplace injuries every year. Some common risks include:

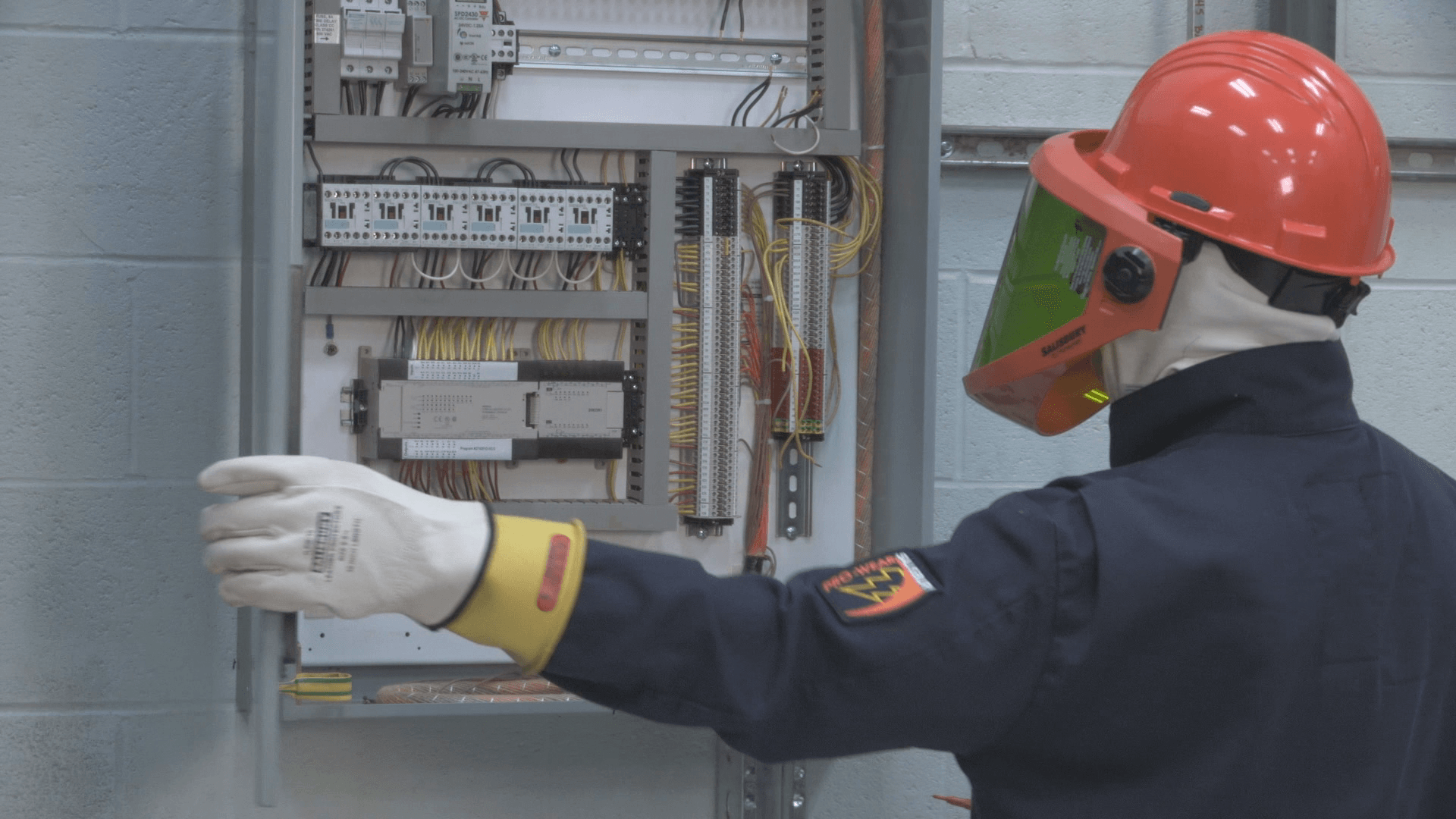

Electrical Arc Flashes

Sudden, high-temperature flashes caused by electrical discharges that can lead to severe burns.

Electrical Shocks

Resulting from direct or indirect contact with energized equipment, leading to injuries or even cardiac failure.

Fires and Explosions

Faulty wiring or equipment can trigger dangerous fires, affecting not just workers but entire facilities.

Prevent Electrical Hazards with Safety Training

Don’t you think they deserve the best electrical training possible?

Electrical safety training expert Len Cicero has years of onsite troubleshooting, maintenance and safety

experience and has developed both online electrical safety programs as well in-class, informal ‘tailgate’

type electrical safety classes which allow students to experience real life scenarios and learn about real

life situations in a safe environment.

Len has made a name for himself in the electrical safety industry by using an interactive, casual 'shop talk' approach which provides a more engaging and effective learning experience.

What is Meant By Arc Flash?

Arc flash hazard — a source of possible injury or damage to health associated with the release of energy caused by an electric arc.

The likelihood of occurrence of an arc flash incident increases when energized electrical conductors or circuit parts are exposed or when they are within equipment in a guarded or enclosed condition, if a person is interacting with the equipment in a manner that could cause an electric arc.

An arc flash incident is not likely to occur during normal operation of equipment that is in a normal equipment condition

The Key Components of Electrical Safety Training

Electrical safety training programs for non-electrical workers typically include essential topics such as:

Recognizing Hazards

Understanding electrical arcs, shocks, and other common risks.

Workplace Safety Practices

Learning to use lockout/tagout procedures to ensure equipment is de-energized before maintenance.

Emergency Response

Knowing what to do in case of an incident, including first aid and reporting protocols.

Customized Training Modules

Tailored to the specific job roles and risk scenarios of the workforce, ensuring relevance and engagement.

ARCFLASH

Why Non-Electrical Workers Need Electrical Safety Training

While electricians undergo rigorous training to manage these risks, many non-electrical workers lack the same level of preparedness. Training

bridges this gap by:

Increasing Awareness:

Workers learn to recognize potential electrical hazards in their specific job environments, ensuring vigilance at all times.

Teaching Practical Safety Protocols:

Training programs like those based on CSA Z462 standards outline measures employees must take, such as maintaining safe distances from energized equipment or wearing appropriate personal protective equipment (PPE).

Reducing Workplace Incidents:

By equipping workers with the knowledge to identify and avoid risks, businesses significantly minimize accidents.

Building Confidence:

Employees feel more secure knowing they’re prepared to handle electrical safety challenges, fostering a stronger sense of individual responsibility in the workplace.