Electrical Safety & Lockout Services During The COVID-19 Pandemic & More Valuable Information.

At Arcflsah.ca safety isn't just something we train, but rather a value that we live by. Our hearts truly go out to all of those who have been affected by the COVID-19 pandemic and appreciate all of the hard work and sacrifices being made by all of the frontline workers. We want to let you know that during this time we are taking proper precautions to help keep everyone safe during this difficult time and are still available to assist you should you need us! Online electrical safety courses and other resources are also available here

We're all in this together!

Circuit Breaker Lockout Panel Lockout®

In my travels over the past

26 years a common question that I get asked from fellow electricians is “how do

I lockout a circuit breaker in a panel”. There are a number of universal

circuit breaker lockout devices available on the market that are well made and

will successfully lockout the breaker with a lockout device and tag attached.

The challenges are, depending on the age of the panel and the depth of the

trim, the panel door may not close or may remain ajar when one attaches a

lockout device. This can be particularly problematic in public areas. In

addition, as good as some of the circuit breaker lockout devices are, they may

not adopt to all manufacturers.

Having said this, something maintenance personnel may consider is a Panel Lockout®. It locks out circuit breakers by locking out the entire electrical panel. It attaches to the panel cover screws and keeps the panel door locked. The device encapsulates two screws which prevents the panel cover from being removed. The circuit breakers remain locked out while work is being done. A tag (if used) has the contact information of the worker in case access to the panel is needed.

The Panel Lockout® locks any size, brand or type breaker. Several breakers can be locked out with one padlock.

If your panel has no screws exposed on the panel there are clips available for these panels, they come with installation instructions. If you have a panel without screws, and you don’t think the clips will work, please call us for additional options.

The Panel Lockout® can also used to prevent shutdowns of critical equipment. It stops unauthorized persons from accessing electrical circuit breaker panels, security panels and data center panels. Lock the panel so that only those that are authorized have the key. Therefore, circuit breakers remain locked on.

The Panel Lockout® device can be more secure and versatile than individual circuit breaker lockouts. For instance, it can lock out several breakers with one lock. In addition, the panel door is locked closed with the Panel Lockout®. As mentioned, the panel door may remain ajar with circuit breaker lockouts. The Panel Lockout® is universal for most panels. Also, circuit breaker lockouts may fall off and can be difficult to install because there is a chance of tripping an adjacent breaker. But the Panel lockout® is sturdy and can not fall off. There is no chance of inadvertently tripping another breaker. It installs in seconds. In conclusion, the Panel Lockout® is a faster, safer and less expensive way to lockout out a circuit breaker!

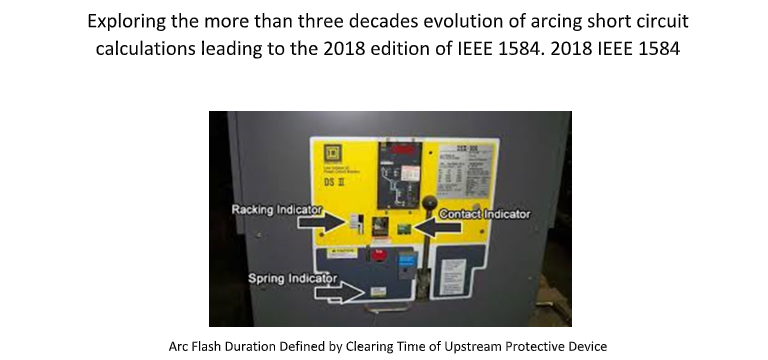

Arcing Short Circuit CurrentBy Jim Phillips, P.E.

When calculating the incident energy and arc flash boundary as part of an arc flash study/risk assessment, one of the main variables is the arcing short circuit current. This is not the same as the traditional “bolted” short circuit current

that is often used to evaluate the interrupting rating of protective devices. The “arcing” short circuit current flows across an air gap during an arc flash and because of the additional impedance from the arc is always less than the bolted short circuit current.

Why would less current be so important? It seems like more current would be worse. It is because another very important variable is the duration of the arc flash which is normally defined by how long it takes an upstream protective device to trip.

The lower arcing current may cause a protective device to take longer to trip - resulting in a greater (and more dangerous) incident energy. 1980’S - NO ARCING CURRENT There has been quite an evolution in how the arcing short circuit current is handled. Back in the 1980’s a.k.a. the early days of arc flash calculations, the equations were quite primitive by today’s standards. In fact, the arcing current was not even considered - only the bolted short circuit current was used.

When determining how long a protective device may take to operate, using the bolted short circuit could indicate the protective device trips instantaneously resulting in a lower incident energy when in fact, the lower (and unknown) arcing current could actually result in the device taking longer to trip. 2000 –BOLTED CURRENT AND 38 PERCENT Equations from a technical paper published in 2000 are listed in CSA Z462 Annex D. These equations are based on actual

arc flash testing – a significant improvement. However, there was still no equation for calculating the arcing current. Instead, this method contains a “work around” for arcing current which states: “For 480 and 600-volt systems, the industry accepted minimum level for a sustaining arcing fault is 38 percent of the available bolted fault” That was it. Just multiply the bolted fault current by 38 percent and evaluate the lower current to see if it resulted in a longer

device clearing time and a worst-case incident energy. 2002 - ARCING CURRENT AND 85 PERCENT When the first edition of IEEE 1584 was published in 2002, one of more significant improvements was the introduction of arcing short circuit current equations. However, since there could be many unknown factors that influence the actual arcing current, it was commonly referred to as “estimate”. As an estimate, what if the actual arcing current was lower? It could again possibly result in the protective device taking longer to operate and lead to a greater incident energy. The solution? Add an additional step where the estimated arcing current would simply be multiplied by 85 percent and the protective device operating time would be re-evaluated with the slightly lower current. The 100% case and 85% case would be compared

and the worst case would be used for the study result. The 85% multiplier was used for all arcing current calculations for systems under 1000 Volts. 2018 – ARCING CURRENT AND VARCF Based on almost 2000 new arc flash tests, the 2018 Edition of IEEE 1584 has made further improvements to the arcing current calculations for greater accuracy. However, the new equations are much more complex and include different electrode configurations, ten different

coefficients as well as other variables. The process involves several calculation steps including determining the “Intermediate Average Arcing Current” with equations based on 600, 2700 and 14,300 volts.

The second step is to use the intermediate current(s) and solve for the final arcing current at the specific system voltage. Similar to the 2002, edition, a second arc duration is calculated using a reduced arcing current to determine if there is an effect on the protective device operating time. Unlike the fixed value of 85% used in the 2002 edition, the 2018 edition

has introduced a new equation for an Arcing Current Variation Correction Factor VarCf which is used for all voltages from 208 to 15,000. The VarCf is heavily voltage dependent and has the greatest impact at voltages between 208 to 600 volts. THE EVOLUTION CONTINUES It has taken several decades, hundreds of people, tens of thousands of manhours and millions of dollars in research to move our understanding of arc flash and related calculations to this level.

Some say the cost and time is too much. For electrical worker’s that have survived an arc flash with minimal or no injuries because of this effort, they know it is well worth it.

Based on my article originally published in Electrical Contractor Magazine – March 2019 Jim Phillips, P.E. founder of Brainfiller.com and ArcFlashForum.com is Vice-Chair of IEEE 1584, Steering Committee member IEEE/NFPA Arc Flash Collaborative Research Project, and International Chair of IEC TC78 Live Working Committee. He is a Senior Member of IEEE, Member of ASTM, NFPA and the IET.

"During this time of isolation, join our friends at

www.ArcFlashForum.com

for discussions about arc flash and electrical safety. The forum was created in 2007 and has gained a global following which includes a section devoted to CSA Z462. See you there!"

- Jim Phillips

During This Time Of Crisis Help When You Can!

That is me - Len behind the N95 mask stocking shelves and helping out at the Good Shepherd Food Bank in Hamilton ON. At this time of world crisis, it is good to help with the underprivileged. The Good Shepherd is a wonderful and caring organization!

Electrical Safety Assistance? There’s A FREE App For That!

Don’t forget, our NEW Arc Flash Electrical Worker Quick Field Guide APP is available on Google Play for FREE! Download it Here !

We hope you and your loved ones are staying safe and healthy, remember we are here if you need us! As always, you are invited to contribute a story or a question that you would like to bring forward to other readers, related to workplace electrical safety or lockout, including PPE and safety equipment.

Please send your stories and questions to Len at len@arcflash.ca . You can also continue the conversation with us on our Linkden Workplace Electrical Safety Communications group!