March Electrical Safety Announcements, Exciting News Inside!

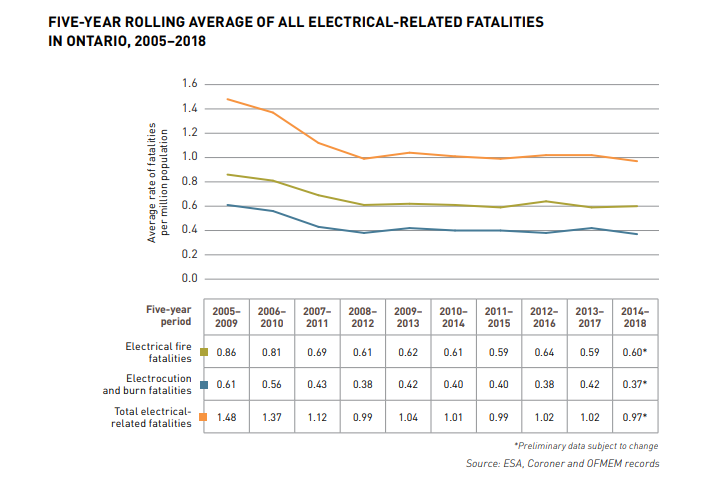

The 2018 Ontario Electrical Safety Report Is Now Available!

Overall, the 2018 OESR shows a downward trend in electrical fatalities and electrical injuries in Ontario . But there is still more work to do! Take a look at the full document here,and feel free to email or call Len with any questions you may have!

Exciting News! CSA Z460 The Control of Hazardous Energy - Lockout and Other Methods!

The third edition of CSA Z460, Control of hazardous energy — Lockout and other methods has been just released. This supersedes the previous editions published in 2013 and 2005.

This Standard provides for flexibility in hazardous energy control methodology decisions as part of an occupational health and safety management system (see CSA Z1000). Other methods are based on risk assessment and application of the classic hazard control hierarchy (see Clause 7.4.4). However, lockout is emphasized as the primary approach to hazardous energy control.

In the creation of this third edition, the following specified changes have been incorporated:

a) clarification of requirement for viewing ports and reference to guidance on nomenclature in Clause

5.2.4;

b) clarification of what is considered to be a remote location and changes to control requirements for

remote locations in Clause 7.3.9;

c) substantive changes to Clause 7.4 (other control methods) for purposes of clarity;

d) expansion of Annex C updating examples on application of risk assessment;

e) addition of guidance on nomenclature in Annex E;

f) realigned and expanded Annexes D, E, F, G, and H as follows:

i) D1 — Policy;

ii) D2 — Individual lock-out procedure;

iii) D3 — Individual lock-out flowchart;

iv) D4 — Sample approved energy control procedure;

v) E1 — Nomenclature standards;

vi) E2 — Placard examples;

vii) F1 — Group lockout procedures;

viii) F2 — Group lockout flowchart;

ix) F3 — Standard group lockout station — Picture;

x) F4 — Pictorial representation of a group lockout;

xi) F5 — Security pyramid example;

xii) F6 — Group lockout with use of satellite lockbox;

xiii) F7 — Flowchart for group lockout with use of satellite lockbox;

xiv) F8 — Complex group lockout; and

xv) F9 — Lock removal procedures;

g) addition of Annex I — application to construction sites;

h) expansion of Annex M on mobile equipment;

i) addition of Annex S — example of decision-making process for other control methods; and

j) addition of Annex T — consideration of human performance factors.

Please contact Len for further information and clarification on these changes, or any assistance required in your in-house Lockout Program

‘You wouldn’t be interested in that’: Fighting stereotypes about women in the trades

Did you catch the article about women in trades published on March 6th on TVO.org? If you missed it, it was a great one and I've shared it below! Enjoy and let me know what you think.

In 2015, Rebecca Chenier was looking for a new career. She and her three kids had just returned from living in Costa Rica, where she’d waitressed and run a surf camp. She’d separated from her husband and was living with her parents in Windsor. It was, she says, a “restarting phase of life.”

She saw an ad on social media for a free program that trained women to become industrial mechanical millwrights. She wasn’t entirely sure what that was, but she knew it was a skilled trade — and liked that the program was for women.

Chenier mentioned it to a counsellor at the local career centre. “You wouldn’t be interested in that,” she remembers him saying. “That’s a dirty job.”

But Chenier had done reasonably well in machine shop in high school. She could have done better, she says: the teacher was so elated to have a female student in his class that he would often let her leave and not finish projects. “If I just showed up, that was good enough for the teacher,” she says. “He didn’t take me seriously at all, so I didn’t take it seriously.”

So she asked the counsellor to help her apply to the program, which was being run through Women’s Enterprise Skilled Training

of Windsor. Although the qualifying week was already underway, Chenier showed up and aced the hands-on work and culminating math test and soon found herself in a pre-apprenticeship college program.

When she finished a few months later, in late 2015, she found herself with three job interviews — and then three job offers. By January, she was apprenticing as a machinist at a factory in Windsor, where she cuts materials using machines and tools, following a blueprint and often using a computer. She went to school a few nights a week and completed her classroom education, apprenticeship hours, and Red Seal certification

last summer.

“It was a huge life change and a big adjustment, but I loved it,” she says. She likes that her job is different almost every day and that the pay is good — she’s now bought a house and a van: “I have a career I can be proud of.”

Canada and Ontario are facing a dire shortage of workers in the skilled trades. Ontario will need to hire 103,900 in the construction and maintenance industries over the next decade, as 91,100 people are set to retire, according to a BuildForce Canada report. Meanwhile, the Ontario government

says that one in five new jobs in the province over the next five years is expected to be in the trades.

More women joining these professions could help. Of the 140 or so skilled trades registered in the province, women make up a hefty percentage of service-sector jobs, such as hairdresser, cook, child and youth worker, and education assistant, but their numbers in the construction, industrial, and motive-power trades hover between 4 and 6 per cent.

Skilled-trade gigs can offer better economic prospects for some women. Statistics Canada

data shows that hairdressers make some of the lowest wages in the skilled trades — heavy-duty equipment technicians and steamfitter-pipefitters make an average of more than $100,000 just four years after getting certified.

But preconceptions about what the skilled trades are and who can do them can seem to rule them out as options. “A lot of it is still about stereotypes,” says Nadine Jannetta, liaison officer for the Engineering, Technology and Trades for Women

program at Conestoga College. “Women think they’re not cut out for these jobs or they can’t do it. They’re not sure they’re a fit.”

Many people, for example, think the trades require physical strength. In fact, Canadian health-and-safety guidelines

indicate that the “recommended maximum weight to be lifted, under perfect lifting conditions” is 23 kilograms. And many manual tasks have been automated.

“There are a lot of barriers to getting women into higher-paying positions,” says Nour Hachem-Fawaz, founder of Build a Dream

, a Windsor-based non-profit that encourages women to join STEM professions, including skilled trades. “We still define work-related positions by gender,” she says. “That should have nothing to do with the job.”

The province runs a number of programs intended to encourage women to join these professions. The Women in Skilled Trades and Information Technology Training

programs, for example, which provide free training for small groups of women in specific trades, are offered at various colleges throughout Ontario. Spurred by concerns about skilled-trade shortages, the government has regularly been announcing new funding, some of which targets women — one program, announced last fall, will see 24 women

receive training as horticultural technicians or arborists at Humber College. The federal government, too, is offering support: it just gave Build a Dream $728,000 for a countrywide roll-out of an outreach for teen girls.

Women who train for a trade, though, often face barriers at work. Annastacia Plaskos, owner of a home-renovation business in Toronto, has a crew of seven women and one man who do tile setting, carpentry, and drywalling. Before she started Fit It Females in 2015, she’d called companies advertising for a home-renovation worker. “As soon as they heard my voice, they’d say they were not hiring.” Chenier’s company, she says, regularly hires women, but it’s still a male-dominated environment: “There have been comments made. Little things, like people saying, ‘Don’t swear, there’s a lady present.’”

It’s not just about getting women in the industry,” says Hachem-Fawaz. “It’s about ensuring that we’re able to retain women in the industry.” France Daviault, executive director of the Canadian Apprenticeship Forum

, which does research and runs events on behalf of the trades industry nationally, agrees that “there are issues of respectful workplaces that need to be addressed.”

Daviault says the Canadian Apprenticeship Forum has been developing a new national strategy for women in the skilled trades. Set to launch this spring, it will include a percentage target for women in these professions and recommendations for how to reach it. “We’re creating a movement,” she says.

Some companies may fear change and be reluctant to welcome women. But, Jannetta notes, Conestoga frequently gets calls from companies asking when the WIST cohort will graduate, because they’re looking to hire. When Plaskos calls on a trusted Toronto-based female electrician, she says, she often can’t take the job: “She’s always busy, I can never get her. She’s very good at her job, and everyone wants to hire a woman. So it’s a win-win for her.”

Electrical Safety Assistance? There’s A FREE App For That!

Don’t forget, our NEW Arc Flash Electrical Worker Quick Field Guide APP is available on Google Play for FREE! Download it Here!

We hope you enjoyed all of the information in our March Newsletter and look forward to hearing from you, as well as bringing more up-to-date electrical safety information and tips in our Summer Newsletter! As always, you are invited to contribute a story or a question that you would like to bring forward to other readers, related to workplace electrical safety or lockout, including PPE and safety equipment.

Please send your stories and questions to Len at len@arcflash.ca . You can also continue the conversation with us on our Linkden Workplace Electrical Safety Communications group!