What is an Arc Flash and How to Prevent It

For electrical engineers, electricians, and safety managers, "arc flash" is a term that carries significant weight. Arc flash incidents are one of the most dangerous and potentially catastrophic hazards in the electrical industry. But what exactly is an arc flash, and more importantly, how can you prevent it?

This blog will explain what arc flash is, why it occurs, and practical ways to safeguard your workplace and team from its dangers.

What is an Arc Flash?

An arc flash is a sudden release of energy caused by an electrical arc. When an unintended electrical connection occurs between two conductors or a conductor and a ground, an arc can form, creating intense heat, a blinding flash of light, and an explosive force.

The temperature of an arc flash can reach up to 35,000°F, which is hotter than the surface of the sun. The intense energy released can result in severe burns, equipment damage, fires, and even fatalities.

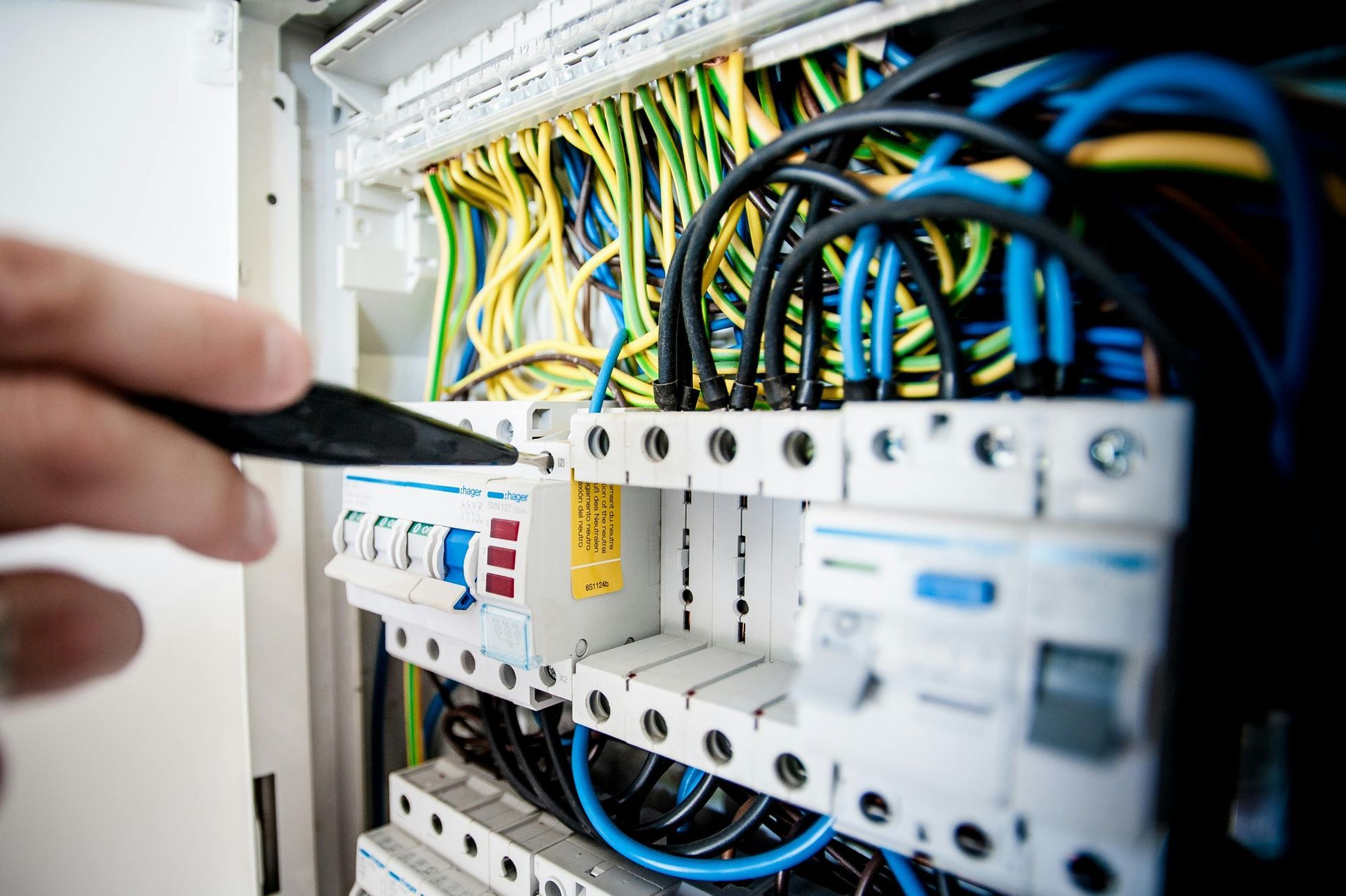

An arc flash can happen in various settings, including industrial facilities, commercial buildings, and construction sites. Given the nature of electrical systems, anyone working near high-voltage equipment or conducting maintenance is at substantial risk.

Common Causes of an Arc Flash

- Faulty or damaged equipment

- Improper installation of devices or systems

- Dust or debris accumulation in switchgear

- Human error, such as accidentally dropping a tool into live equipment

- Lack of appropriate preventative maintenance

The Consequences of an Arc Flash

- Serious Injuries: Severe burns, hearing loss, and eye damage are common in arc flash incidents.

- Equipment Damage: The explosive force can damage or destroy electrical equipment, leading to costly downtime.

- Legal & Financial Liability: Failing to prevent arc flash incidents could result in regulatory fines or lawsuits.

How to Prevent an Arc Flash

Preventing arc flash isn’t just about compliance; it’s about creating a safer workplace for your team. Below are the key measures you can take to reduce the risk:

1. Conduct an Arc Flash Risk Assessment:

Before taking any action, performing a detailed risk assessment is critical. This involves identifying equipment and work tasks that have arc flash hazards, calculating the level of risk, and assigning safety zones.

Arc flash analysis will provide you with key data, including:

- Incident energy levels

- Approach boundaries

- Proper personal protective equipment (PPE) requirements

2. Use Personal Protective Equipment (PPE)

Using the right PPE can be life-saving. Arc-rated clothing, gloves, face shields, and hearing protection are designed to minimize injuries during an arc flash event. Ensure all PPE is compliant with industry standards, such as NFPA 70E.

3. Implement Regular Maintenance

Poorly maintained electrical systems are a leading cause of arc flash incidents. Establish a preventative maintenance schedule to keep all equipment clean, inspected, and in working condition.

4. Provide Comprehensive Arc Flash Training

One of the most effective ways to prevent arc flash is to ensure your team is well-trained. Employees and contractors must understand the hazards, safety procedures, and proper use of PPE.

If you’re looking to educate your team, call 905-691-2880 today to learn about comprehensive arc flash training sessions.

5. Label Equipment Properly

Arc flash labels are essential for warning personnel of the potential hazards. These labels include critical information such as voltage levels, arc flash boundaries, and PPE requirements.

6. Utilize Engineering Controls

When possible, incorporate engineering solutions that reduce arc flash risk. For example:

- Install arc-resistant equipment

- Use remote racking and remote operating technology

- Implement current-limiting fuses and circuit breakers

7. Develop an Electrical Safety Program

A written electrical safety program ensures that every member of your team knows the required procedures to work safely. Include a clear policy for:

- Identifying live systems

- De-energizing equipment whenever possible

- Emergency response in the event of an arc flash

Stay Safe and Prevent Arc Flash Hazards

Arc flash incidents are preventable with the right approach, tools, and training. By incorporating these best practices into your workplace, you protect not only your team but also your equipment and bottom line.

Don't wait for an incident to remind you of the importance of safety. Train your team, stay proactive, and assess your systems regularly to keep hazards at bay.

Need Expert Training for Your Team?

Educating your workforce about arc flash is one of the most effective safety measures.

Call 905-691-2880 today to schedule professional arc flash safety training. Make safety your priority!