Kick Off Summer Safely With Answers To Some Common Arc Flash Questions...

With summer on the horizon, things are heating up in the arcflash.ca world! In our latest newsletter we’re going to touch base on some common, but vital, Arc Flash Q&As, the importance of keeping your work van clean, and the introduction of our brand new arcflash.ca course: The Safe Application of Fuses For Industrial Mechanics & Millwrights. Looking forward to your feedback on these topics, as well as answering any electrical safety questions you may have!

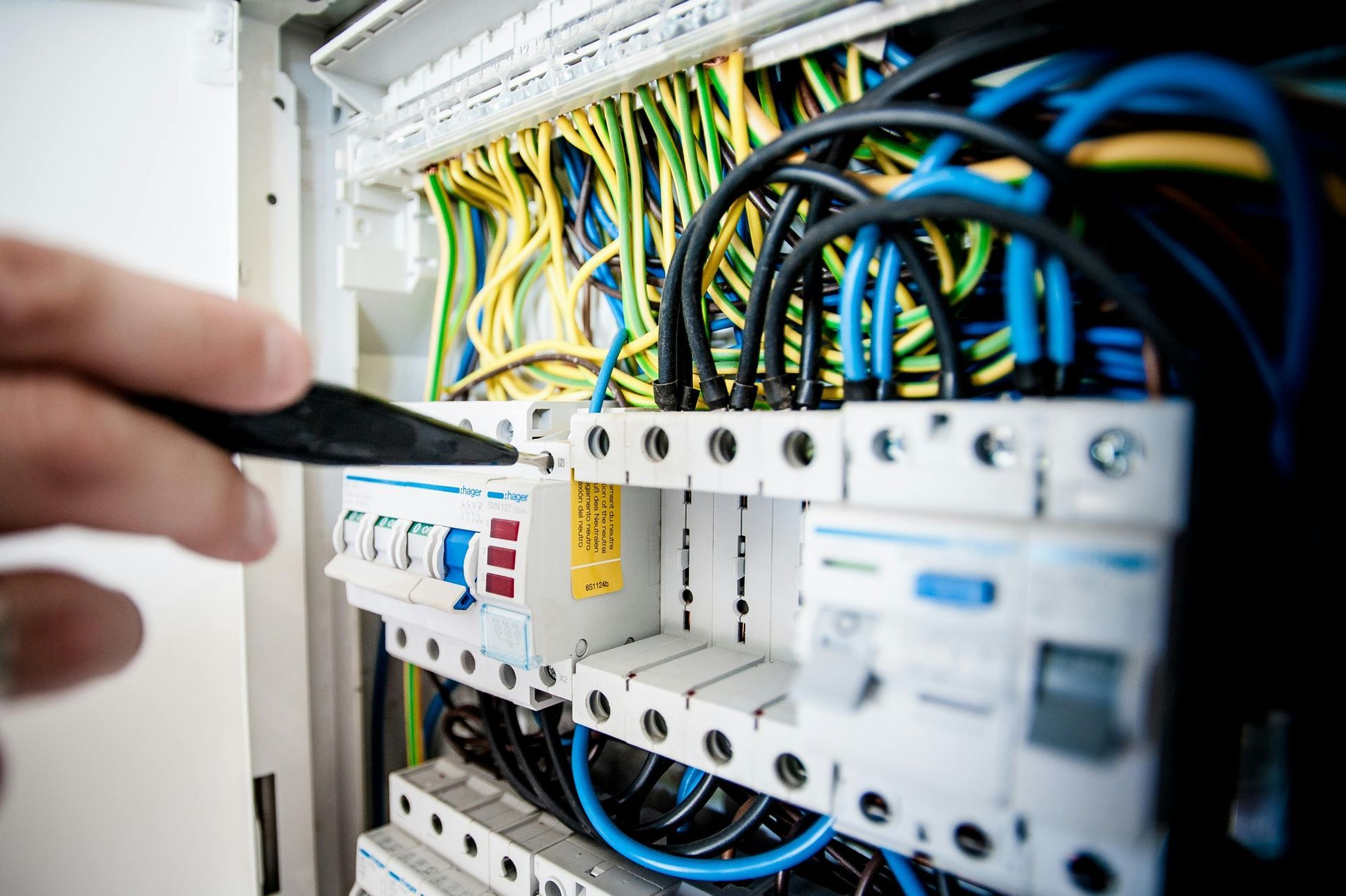

Common Arc Flash Q&As Answered!

|

Hey Electricians, Don’t Let Nasty Germs Hitch A Ride In Your Work Van!

A tradesperson’s work van often acts as their second home, with many drivers spending much of their time on the road or taking breaks behind the wheel. While many people wouldn’t dream of leaving their home uncleaned, a recent survey revealed how dirty a tradesperson’s work vehicle can get.

Confused.com, a British financial services comparison website, partnered with the School of Biological Sciences at the University of Essex in Colchester, U.K., to investigate the various germs living in six trade vans belonging to:

·A builder

·A carpenter

·A dog groomer

·An electrician

·A bricklayer

·A plumber

The results showed that vans can harbor numerous germs, some of which can pose a serious threat to the health of their drivers. Findings revealed:

The handbrake is the most germ-ridden area, carrying germs that can cause skin or respiratory infections.

The most prominent bacteria found was Staphylococcus aureus — the effects of which can range from mild skin infections to life-threatening diseases.

Pathogens known to cause pneumonia and endocarditis, which can be fatal in extreme cases, were found in several areas of the vans.

Below are how the service vehicles ranked in order of dirtiness, including the tested toilet door handle:

·Bricklayer

·Builder

·Electrician

·Dog groomer

·Carpenter

·Plumber

·Toilet door handle

According to a survey of 500 van drivers conducted by Confused.com, nearly one in 10 (8%) admit they’ll only clean the inside of their van when it starts to smell, while only one in three (29%) will empty trash from their van daily. One in seven (14%) admit to never cleaning their van at all. Furthermore, more than half (55%) of respondents admitted to eating food in their van and then leaving the half-eaten food in place for as long as three days. More than one in seven (15%) claim to leave used tissues in their van frequently. Only one in seven (14%) said they wipe the surface immediately if they sneeze.

To help keep your work vehicle more health-friendly, see these tips on deep cleaning it.

For more information, click here

Have You Heard About The ***NEW*** Arcflash.ca Course: The Safe Application of Fuses For Industrial Mechanics & Millwrights

This course is intended to provide Millwrights and

Industrial Mechanics with a better understanding of Canadian fuse products and

their applications in order to minimize the possibility of misapplication,

ensuring the safety of both equipment and personnel. In addition to providing,

through practical scenarios the safe application of fuses to avoid personal

injury.

1 day- 6.0 hours

Contact us today for more information.

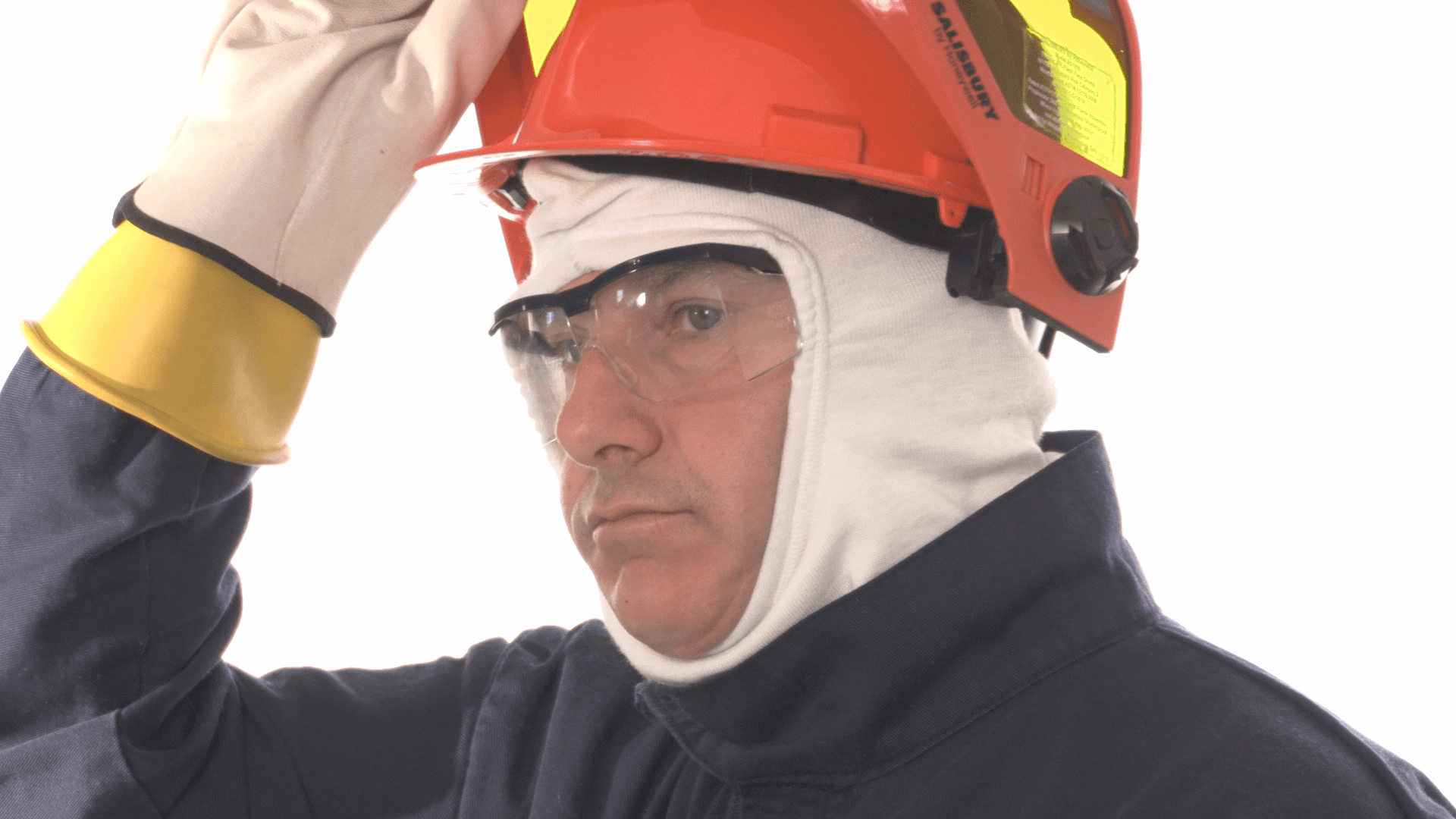

Workplace Electrical Safety Online Course - $100 Per Person

The workplace electrical safety online course is based on the 2018 edition of CSA Z462. The course has been developed for workers who are performing electrical work on energized systems. It provides guidance on industry best practices for the prevention of injury from arc flash and shock.

Click here for more information or to purchase.

Electrical Safety Assistance? There’s An App For That!

Don’t forget, our NEW Arc Flash Electrical Worker Quick Field Guide APP is available on Google Play for just $2.99!

We hope you enjoyed all of the information in our Spring Newsletter and look forward to hearing from you, as well as bringing more up-to-date electrical safety information and tips in our Summer Newsletter! As always, you are invited to contribute a story or a question that you would like to bring forward to other readers, related to workplace electrical safety or lockout, including PPE and safety equipment.

Please send your stories and questions to Len at len@arcflash.ca . You can also continue the conversation with us on our Linkden Workplace Electrical Safety Communications group!